The evolution of manufacturing and branding in various industries has significantly transformed with the advent of technologies like the Trademark Printing Machine. This innovative device not only enhances the production capabilities but also ensures that brands maintain their identity through consistent and high-quality representations. As noted by industry expert Dr. Emily Carter, “The Trademark Printing Machine is revolutionizing how businesses approach brand authenticity, enabling them to produce striking prints that resonate with their audience effectively.”

In our fast-paced market, companies seek to stand out, and the Trademark Printing Machine plays a pivotal role in achieving this. By utilizing advanced printing techniques, it creates distinct trademarks and logos that are essential for product recognition and customer loyalty. This technology is not just about aesthetics; it encompasses numerous aspects of production efficiency, scalability, and sustainability.

Understanding how a Trademark Printing Machine operates within industrial applications can provide valuable insights into its broader implications for branding and marketing strategies. As industries continue to adapt and innovate, the importance of such machines will only grow, making it vital for businesses to leverage their potential fully. Through a closer examination of their functionality and impact, we can appreciate the role they play in shaping successful brand narratives in today's competitive landscape.

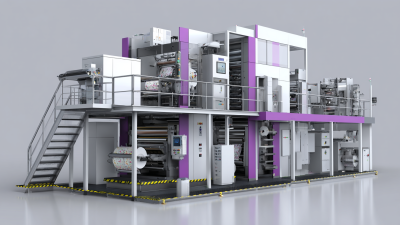

A trademark printing machine is a specialized device designed for the precise and efficient application of trademarks, logos, and other identifying marks onto various products. These machines are integral in industries such as packaging, textiles, and manufacturing, where consistent branding is crucial. They can print on a wide range of substrates, including paper, plastic, metal, and glass, ensuring that businesses can showcase their brand identity effectively across different products.

The operation of a trademark printing machine typically involves several key components, including a printing plate, ink reservoirs, and a substrate feed system. The printing process can vary, utilizing techniques such as flexography, gravure, or digital printing, depending on the quality and volume requirements. As the substrate passes through the machine, the printing plate transfers the ink onto the surface, creating a clear and durable trademark that can withstand various environmental conditions. This technology not only enhances the visual appeal of products but also helps in enforcing brand recognition in a competitive market.

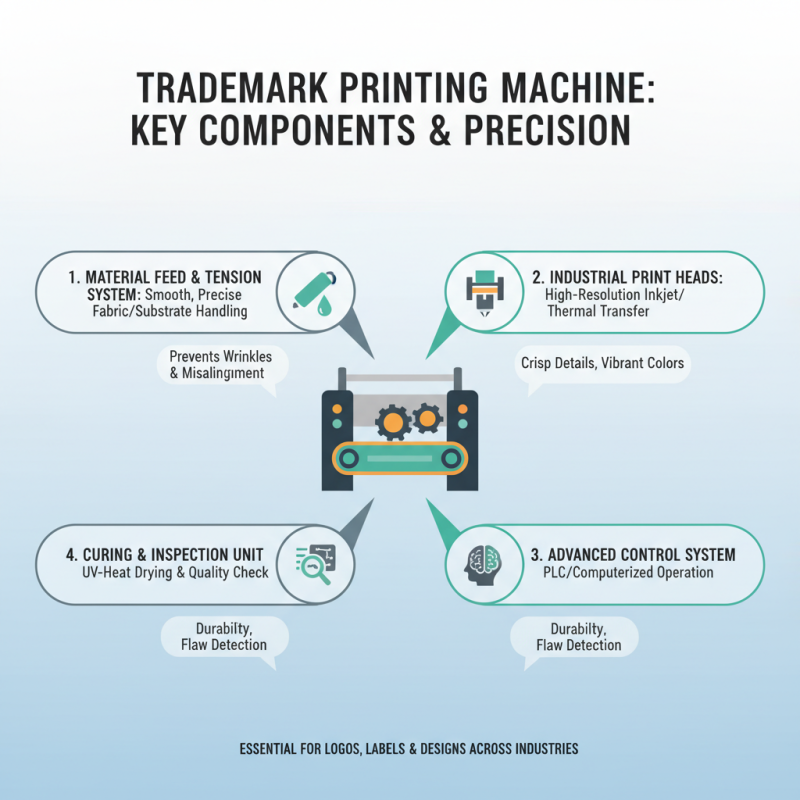

A trademark printing machine is an essential tool in various industries for producing high-quality prints that showcase logos, labels, and designs. The key components of these machines play a critical role in ensuring efficiency and precision during the printing process.

One of the main components is the printing head, which is responsible for transferring ink onto the material. Advanced printing heads can produce intricate designs with great accuracy, allowing for detailed representations of trademarks. Additionally, the ink delivery system is crucial, as it ensures a consistent flow of ink, preventing clogging and ensuring that colors remain vibrant.

Another important element is the substrate feeder, which holds and feeds the material to be printed through the machine. This component needs to be adjustable to accommodate various sizes and types of materials, whether they are labels, packaging, or fabric. Finally, the drying unit enables quick drying of the printed designs, increasing productivity by minimizing wait times before further processing or handling. The combination of these components allows trademark printing machines to function effectively in fast-paced production environments.

Trademark printing machines play a crucial role in various industrial settings by ensuring that products are clearly marked and easily identifiable. The operation of these machines typically involves sophisticated technology that allows for high-quality, durable prints on different materials, including plastic, metal, and glass. According to a study by Smithers Pira, the global market for industrial printing is expected to grow to $274 billion by 2025, with a significant portion attributed to advances in printing technology, including trademark printing systems.

In an industrial environment, trademark printing machines operate through a combination of software and hardware designed to produce precise and consistent output. These machines utilize advanced ink formulations that are resistant to smudging, fading, and various environmental factors. This capability is essential for industries such as pharmaceuticals and food and beverage, where labeling accuracy and durability are vital for compliance and consumer safety. Reports indicate that, in sectors like manufacturing, nearly 30% of companies fail to meet labeling standards, which amplifies the need for reliable printing solutions.

The integration of automation into trademark printing processes has also improved efficiency and reduced labor costs. With features such as inline printing, where labels are printed as items move through production lines, businesses can achieve significant time savings. A report from Grand View Research highlights that automated printing technologies can increase productivity by up to 25%. As industrial operations continue to evolve, the importance of trademark printing machines will remain paramount in maintaining brand integrity and operational efficiency.

| Dimension | Description | Applications |

|---|---|---|

| Type of Printing | Digital, Flexographic, Gravure | Labels, Packaging, Tags |

| Speed | Up to 100 meters per minute | High-volume production |

| Print Resolution | 600 x 600 dpi to 1200 x 1200 dpi | Quality-sensitive applications |

| Ink Types | Water-based, Solvent-based, UV-cured | Various substrates and environments |

| Automated Features | Real-time monitoring, Automatic adjustments | Increased efficiency and consistency |

Trademark printing machines play a crucial role in various industries by facilitating the creation of customized branding and identification solutions. One of the most prominent applications is in the packaging sector, where companies utilize these machines to print trademarks, logos, and essential product information directly onto packaging materials. This not only enhances the aesthetic appeal of products but also ensures compliance with regulatory requirements, as vital details about the product are clearly depicted. Additionally, quality and consistency in printing are paramount, ensuring that each package reflects the brand’s image and meets consumer expectations.

Another significant application of trademark printing machines is in the promotional merchandise industry. Businesses often use these machines to produce branded items, such as labels, tags, and direct mail pieces, which help in marketing campaigns. By incorporating distinct trademarks onto promotional products, companies can increase brand visibility and consumer engagement. Furthermore, these machines are versatile, capable of printing on various surfaces and materials, making them ideal for creating unique promotional items that resonate with target audiences across different sectors, from retail to corporate branding.

Trademark printing machines are becoming increasingly essential for businesses seeking to enhance their branding and operational efficiency. One major benefit of these machines is their ability to produce high-quality labels and markings quickly and efficiently. According to a recent market report by Smithers Pira, the label industry is projected to grow at a CAGR of 4.4% through 2024, highlighting the increasing demand for efficient printing solutions in various sectors. Businesses can leverage trademark printing machines to create consistent and professional-looking branding materials that capture customer attention and foster brand loyalty.

Moreover, these machines provide significant cost savings in the long run. Traditional printing processes can be time-consuming and labor-intensive, leading to increased overhead costs. However, trademark printing machines offer automation features that streamline workflow, reduce labor costs, and minimize material waste. A study by the Freedonia Group indicated that companies that adopted advanced printing technologies reported a 20% reduction in production costs. Additionally, the versatility of these machines allows businesses to easily switch between different materials and designs, further enhancing operational flexibility. By integrating trademark printing machines into their production lines, businesses not only improve their efficiency but also position themselves to respond swiftly to market demands and consumer preferences.