The landscape of modern manufacturing is being transformed by technological advancements, with the Automatic Printing Machine at the forefront of this revolution. According to a report by Smithers Pira, the global market for digital printing is expected to reach $29.6 billion by 2024, driven largely by the efficiency and flexibility offered by automatic print technologies. As industries seek to enhance productivity and reduce waste, the adoption of Automatic Printing Machines has surged, providing quicker turnaround times and the ability to produce high-quality prints with minimal human intervention. This innovative equipment not only streamlines production processes but also accommodates customization, allowing businesses to respond rapidly to market demands. As we delve into the ways Automatic Printing Machines are reshaping industries, it becomes clear that their integration is not merely a trend, but a critical step towards optimizing operations and ensuring competitiveness in the evolving digital age.

Automatic printing machines are at the forefront of technological innovation, driving efficiency and quality across various industries. Key technologies such as digital inkjet and laser printing have transformed traditional processes. According to a recent report by Smithers Pira, the global digital printing market is projected to reach $29.79 billion by 2026, growing at a compound annual growth rate (CAGR) of 10.5%. This growth is attributed to the demand for custom printing solutions and shorter print runs, enabling businesses to reduce waste and inventory costs.

The integration of automation and artificial intelligence (AI) in printing processes has further revolutionized the industry. Automated pre-press workflows significantly cut down production times, while AI-driven quality control systems ensure consistent output quality. A study by MarketsandMarkets indicates that the smart printing technology market could grow to $12.4 billion by 2024, as businesses increasingly adopt solutions that enhance operational efficiency. These advancements not only meet the growing consumer demand for personalization but also support sustainable practices through optimized resource usage and reduced environmental impact.

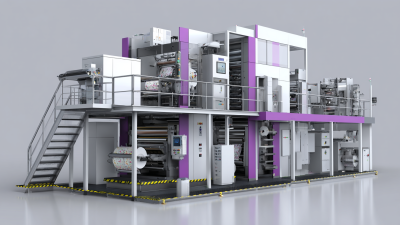

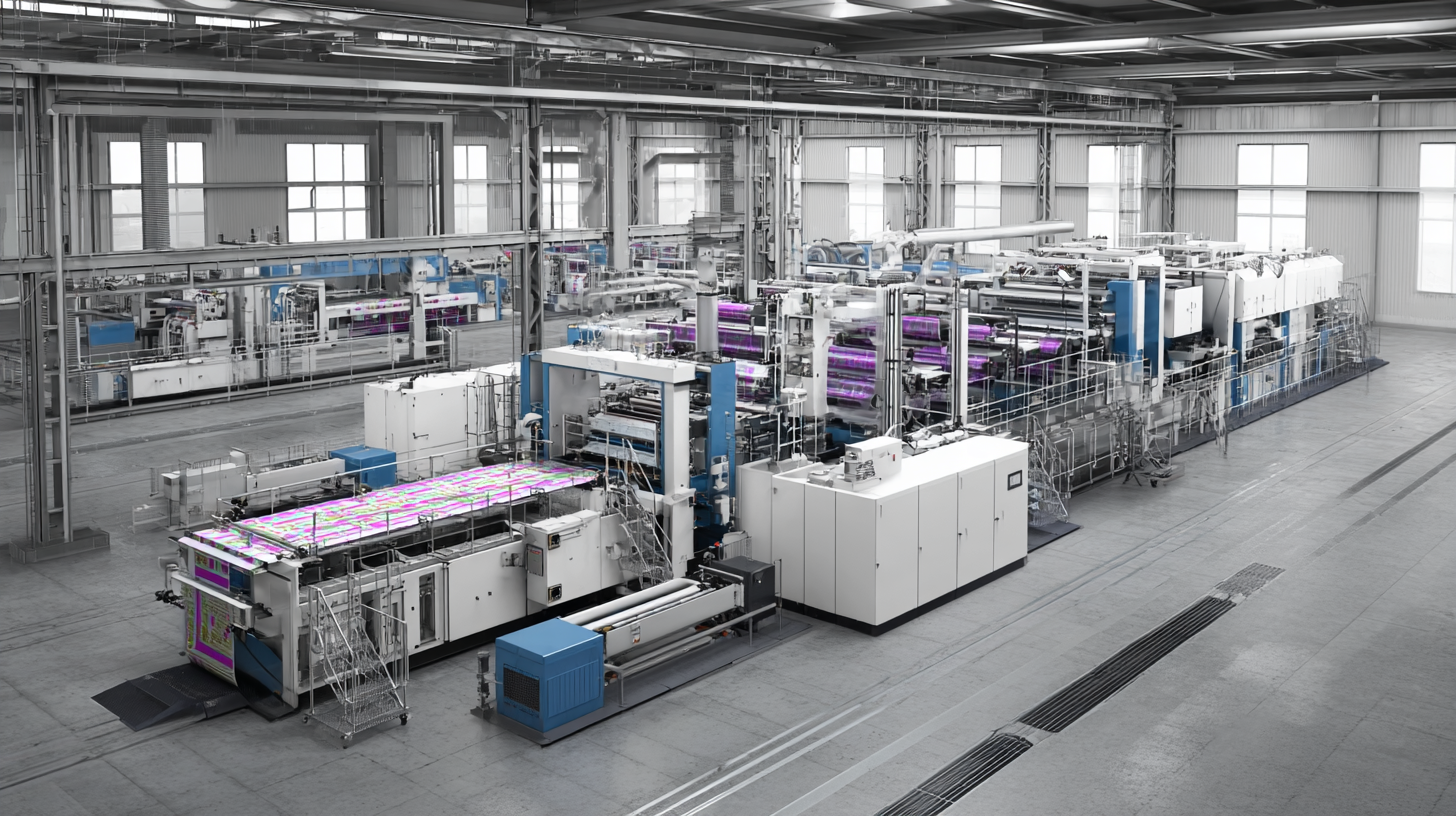

The evolution of automatic printing machines has significantly transformed various industries by streamlining processes, enhancing productivity, and ensuring high-quality output. Different types of automatic printing machines cater to the unique needs of sectors such as textiles, packaging, and commercial printing. For instance, digital printing machines are increasingly popular in the commercial sector due to their ability to produce customized prints quickly and cost-effectively, thereby meeting the demands of on-demand printing.

In the textile industry, rotary screen printing machines are widely embraced for their efficiency in producing intricate designs at high speeds. These machines enable manufacturers to achieve vibrant colors and complex patterns that are essential for creating competitive fashion items. Meanwhile, in the packaging sector, flexographic printing machines play a crucial role in delivering bold graphics and sustained durability on various packaging materials. These advancements illustrate how automatic printing machines are not just tools but are fundamental in driving innovation and fostering growth across different industries.

The integration of automatic printing machines into business operations offers numerous advantages that can significantly enhance productivity and efficiency. One of the most notable benefits is the reduction of manual labor requirements, allowing businesses to allocate their human resources to more strategic tasks. By automating the printing process, companies can minimize errors associated with manual handling, ensuring a higher level of accuracy in their output.

Additionally, automatic printing machines can operate continuously with minimal downtime, which leads to faster production cycles. This increased speed not only meets the growing demands of the market but also allows businesses to respond swiftly to customer needs.

Furthermore, the precision and consistency offered by these machines enable businesses to maintain a high-quality standard across their products, reinforcing brand reputation and customer satisfaction. Overall, the implementation of automatic printing technology is a transformative step that can streamline operations and foster growth in various industries.

When selecting an automatic printing machine, it is crucial to evaluate several key factors that can significantly impact productivity and quality. First, the printing method—whether digital, flexographic, or offset—should align with your business needs. Each method offers distinct advantages, such as speed, cost-effectiveness, and print quality, making it essential to assess your specific requirements before making a choice.

Additionally, consider the machine's capacity and scalability. As businesses grow, so do their printing demands; therefore, investing in a machine that can handle increased volume without compromising quality is vital. Features like quick-change capabilities and automated maintenance systems can further enhance operational efficiency, reducing downtime and maximizing output. Lastly, don’t overlook the importance of customer support and training provided by the manufacturer, as these resources can help ensure a smooth transition and optimal performance from the new equipment.

The automatic printing technology landscape is on the brink of revolutionary changes, with advancements that promise to redefine manufacturing and creative processes across multiple industries. As we delve into future trends, we can anticipate a surge in the integration of artificial intelligence and machine learning. These technologies will enable printing machines to learn and adapt to user preferences, leading to highly personalized products with minimal human intervention. This shift not only enhances efficiency but also reduces waste, aligning with sustainable practices that are becoming increasingly paramount in the global market.

Another significant trend is the expansion of printing applications beyond traditional mediums. Innovations in materials such as 3D printing and multifunctional inks are paving the way for applications in fields like healthcare, architecture, and even fashion. For instance, bioprinting is set to transform the medical industry by enabling the creation of custom tissue and organ structures, while smart textiles will revolutionize the fashion landscape by introducing fabrics that change colors or patterns on demand. As these technologies progress, the capabilities of automatic printing machines will transcend conventional limits, offering solutions that were once deemed impossible.

The chart above illustrates the projected market growth of automatic printing technology over the next five years. The data indicates a significant increase, reflecting advancements in technology and rising demand across various industries.