In today's fast-paced manufacturing environment, the integration of technology is crucial for enhancing productivity and streamlining operations. One of the most significant advancements in this realm is the Automatic Printing Machine, which has revolutionized the way businesses approach printing tasks on their production lines. These machines not only reduce manual labor but also improve accuracy and speed, leading to higher efficiency and lower costs. However, to fully harness the potential of an Automatic Printing Machine, it is essential to implement best practices that can optimize its use in your workflow. This blog will delve into 10 essential tips designed to help you maximize the efficiency of your Automatic Printing Machine, ensuring that it becomes an integral part of your production process and drives your business towards greater success.

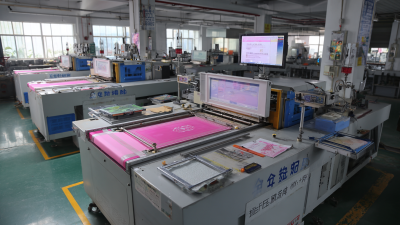

Automatic printing machines are vital components in modern production lines, designed to enhance productivity and ensure consistent quality. Understanding the basics of how these machines operate is crucial for any manufacturing facility aiming to maximize their output. Typically, automatic printing machines utilize advanced technology to streamline the printing process, utilizing features such as automatic feed systems and multi-color printing capabilities. This allows them to handle large volumes of work efficiently while reducing the risk of human error.

The heart of these machines lies in their ability to integrate seamlessly with existing production workflows. They operate using digital control systems that allow for quick adjustments and precise monitoring of print quality. Additionally, many models come equipped with sensors that detect issues in real-time, which means that problems can be addressed without significant downtime. By investing time in understanding these foundational concepts, operators can better manage their equipment and leverage its full potential, thereby achieving greater efficiency in their production lines.

Maintaining printing machines is crucial for achieving optimal performance in your production line. Regular maintenance practices not only prolong the life of these machines but also ensure high-quality output. One essential tip is to establish a routine cleaning schedule. Dust and ink residue can accumulate over time, leading to blockages and reduced efficiency. By regularly cleaning the printing heads, rollers, and surrounding areas, you can prevent these issues and maintain consistent print quality.

Another critical maintenance practice involves monitoring and replacing consumable parts. Components such as ink cartridges, print heads, and transfer belts have a limited lifespan and can significantly affect your printing operations. Keeping an eye on their condition and replacing them proactively will minimize downtime and enhance the overall efficiency of your production line. Additionally, consider implementing a maintenance log to track service schedules and part replacements, ensuring that your machines are always operating at their best.

Integrating automatic printing machines into your production line can significantly enhance workflow efficiency. The first step is to assess the layout of your production area. Ensure that the printing machines are strategically positioned to minimize the distance materials need to travel. This not only reduces handling time but also lowers the risk of errors during transport. Additionally, consider configuring the machines to work in tandem with other automated systems for streamlined operations, such as sorting or packaging.

Another crucial aspect is the implementation of smart software solutions that monitor production speed and quality in real-time. By employing data analytics, you can identify bottlenecks and adjust workflows dynamically. Offering comprehensive training for your staff on the automatic systems will further enhance productivity; well-informed operators can quickly troubleshoot issues and maintain consistent production flow. By prioritizing the integration of printing machines into your processes thoughtfully, you can achieve a more efficient and cohesive production line.

When it comes to maximizing efficiency with automatic printing machines on your production line, making the right adjustments can significantly enhance performance. One key setting to consider is the calibration of the printer's speed and temperature. By optimizing these parameters based on the specific materials being used, you can reduce waste and achieve better print quality. Regular maintenance checks ensure that all components are functioning correctly, minimizing downtime and enhancing reliability.

Another crucial adjustment is to ensure that the software controlling the printer is frequently updated. Utilizing the latest technological advancements can improve processing speeds and streamline workflow, allowing for faster production cycles. Additionally, integrating artificial intelligence into printing systems can enhance their adaptability, allowing for real-time adjustments based on production demands. Taking these steps can lead to substantial improvements in the overall efficiency of your automatic printing operations, ensuring that your production line remains competitive and responsive in a rapidly evolving industry.

Troubleshooting common issues with automatic printing machines in production environments is crucial for maintaining efficiency and minimizing downtime. According to a report by Smithers Pira, production line inefficiencies can account for up to 30% of operational costs in the printing industry. Common problems such as misalignment, ink smudging, and equipment jams can lead to significant production delays and material waste if not addressed promptly. Implementing regular maintenance schedules and training staff on basic troubleshooting techniques can help mitigate these challenges.

In addition, the importance of integrating real-time monitoring systems cannot be overstated. A study by the Freedonia Group indicates that companies utilizing predictive maintenance tools can reduce equipment failure by as much as 50%. Such systems provide valuable insights into machine performance, enabling operators to identify and resolve issues before they escalate into costly breakdowns. By fostering a proactive approach to machine care, production facilities can enhance their overall efficiency and ensure a smoother workflow, thus maximizing the potential of their automatic printing machines.