In the competitive landscape of apparel manufacturing, selecting the right machine for shirt printing is crucial to enhancing production efficiency and adapting to market demands. According to a recent report by Smithers Pira, the global digital textile printing market is projected to reach $4.9 billion by 2024, highlighting the significance of advanced printing technology in driving growth within the industry.

Moreover, the rise of on-demand printing has shifted the focus to machines that offer speed, versatility, and high-quality results. By investing in the appropriate machine for shirt printing, businesses can not only streamline their production processes but also respond swiftly to changing consumer preferences and minimize waste.

Understanding different printing technologies, such as screen printing, direct-to-garment, and dye sublimation, further enables manufacturers to make informed decisions that align with their operational goals.

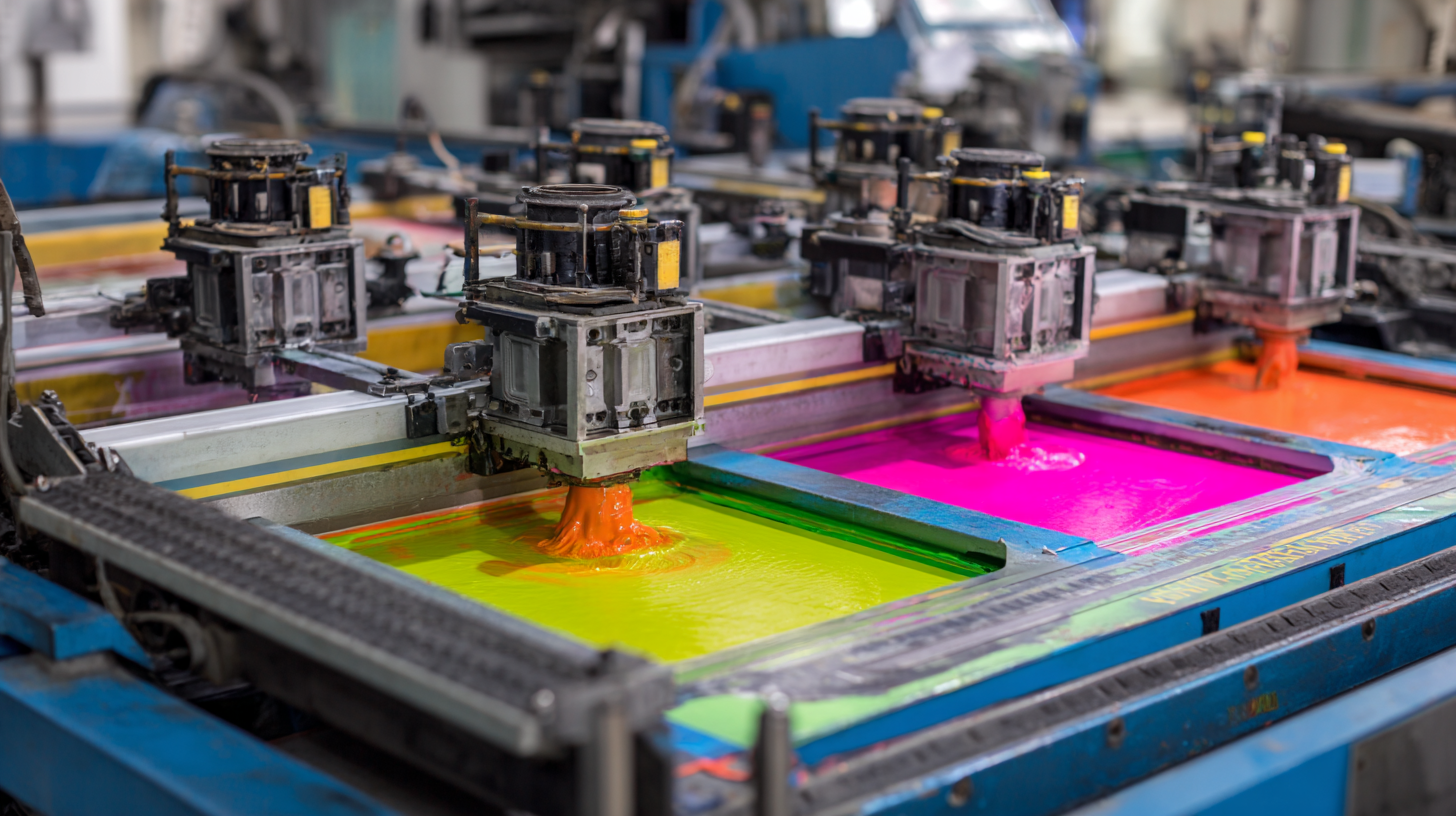

When selecting the best machine for shirt printing, understanding the various printing techniques and their production efficiencies is crucial. Screen printing remains a dominant method due to its scalability and cost-effectiveness, particularly for high-volume runs. Recent studies highlight that employing advancements in screen-printing technology can significantly enhance production efficiency. For example, implementing the Single-Minute Exchange of Dies methodology optimizes setup times, thereby reducing waste and increasing overall throughput.

Conversely, additive manufacturing techniques, including 3D printing, are gaining traction in the apparel industry, especially for customized and on-demand production. As reported, the 3D printing market is projected to exceed $40 billion by 2030, signifying a broader adoption in manufacturing sectors. This shift underscores a trend towards sustainability and reduced environmental impact, with technologies aimed at optimizing fiber morphology gaining popularity. The integration of AI with these methods further enhances adaptability and precision, paving the way for more efficient production processes and helping manufacturers meet evolving consumer demands.

When selecting the best machine for shirt printing, understanding the cost-effectiveness of Direct-to-Garment (DTG) printing versus screen printing is vital. DTG offers a low setup cost, making it ideal for small batches or custom designs. However, the cost per print can be higher than traditional screen printing, especially for large orders. Conversely, screen printing requires a more significant initial investment due to the setup of screens, but it shines in producing high volumes at a lower cost per item, making it suitable for bulk orders.

**Tips:** When deciding between DTG and screen printing, consider the scale of your production. For smaller runs with intricate designs, DTG is often more efficient and cost-effective. In contrast, if you're looking to produce larger quantities with simple designs, screen printing is likely the better financial choice. Additionally, keep in mind the potential for waste—screen printing can generate more fabric waste during setup, while DTG uses ink more efficiently.

Ultimately, evaluating your specific needs, such as order volume and design complexity, will help you make an informed decision. Balancing initial investment and ongoing costs is crucial to maximize your production efficiency in the long run.

| Printing Method | Initial Investment Cost | Operating Costs (per shirt) | Production Speed (shirts/hour) | Print Quality | Best Use Case |

|---|---|---|---|---|---|

| Direct-to-Garment (DTG) | $15,000 | $2.50 | 20 | High | Small runs, detailed designs |

| Screen Printing | $10,000 | $1.00 | 50 | Medium | Large runs, simple designs |

| Sublimation Printing | $12,000 | $2.00 | 25 | High | Polyester fabrics, detailed design |

When it comes to shirt printing, print quality plays a crucial role in customer satisfaction, making it essential to understand machine specifications. According to a recent Smithers report, 45% of customers cite print quality as their top priority when choosing a printed garment. Thus, selecting a machine that can deliver high-resolution prints and vibrant colors is paramount. Key specifications to consider include the print head technology, such as Direct-to-Garment (DTG) or screen printing, which can significantly affect the final product's appearance and durability.

In addition to print quality, the machine's production speed should not be overlooked. The same report indicates that production efficiency is linked to machine capabilities; for instance, DTG printers can produce 20-200 shirts per hour depending on materials and design complexity. Moreover, features like automated color matching and registration can enhance precision, ensuring that colors are consistent across prints. Investing in advanced machines that meet these specifications helps businesses not only satisfy customer demands but also stay competitive in a fast-paced market.

When selecting a printing machine for shirt production, analyzing production speed is crucial. Key metrics to consider include the machine's output per hour, setup time, and maintenance frequency. A high output per hour can significantly enhance productivity, but it should be balanced with the quality of prints produced. Fast machines that compromise on quality can result in high rejection rates, ultimately affecting overall efficiency.

Another important metric is the setup time required to transition between different shirt designs or printing methods. Machines that offer quick changeovers help minimize downtime, allowing manufacturers to respond swiftly to market demands and order variability. Furthermore, understanding the maintenance requirements of a machine is essential for sustained performance; machines that require frequent repairs or are difficult to service can negate gains in efficiency. By focusing on these production speed metrics, businesses can make informed decisions that align with their operational goals and market needs.

The landscape of shirt printing has transformed significantly with the advent of technological advancements, allowing businesses to enhance their productivity like never before. Digital printing technologies, such as Direct-to-Garment (DTG) and dye-sublimation, have emerged as leading options due to their ability to produce high-quality prints with quick turnaround times. These methods enable printers to achieve complex designs and vibrant colors without the need for extensive setup, dramatically reducing production time compared to traditional screen printing.

Furthermore, automation in shirt printing processes plays a crucial role in maximizing efficiency. Modern printing machines equipped with automated features manage everything from color registration to print alignment, thus minimizing human error and expediting workflow. Additionally, integrating software solutions that streamline order management and inventory can further optimize operations, allowing print businesses to handle larger volumes and meet tight deadlines effortlessly. As technology continues to evolve, those in the shirt printing industry must stay informed, adopting the latest innovations to maintain competitive advantages while boosting production capabilities.